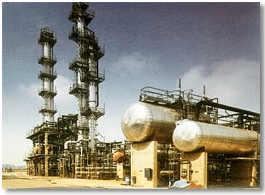

The Methyl Tertiary-Butyl Ether (MTBE) and Tertiary Amyl Methyl Ether (TAME) plants in Killingholme, United Kingdom, include offsite and storage facilities for propane, propylene and methanol for Lindsey Oil Refinery Ltd. The MTBE plant has a rate of 100,000 metric tons (110,200 tons) per year, and the TAME plant has a rate of 50,000 metric tons (55,120 tons) per year.

We developed detailed scale piping models for the units and created isometric drawings showing the pipework and detailed piping material take-off quantities. The project required more than 120 tie-ins into process and utility systems.

To accelerate the project schedule, we utilized several optimization techniques. We fabricated and fireproofed the main steel support structures offsite prior to installation. All the process columns, including the 53-meter (174-foot) high depentanizer distillation column, were fully dressed prior to installation with the main process pipework, access platforms, instrumentation and insulation fitted prior to erection. As the result of careful planning, the project was completed in 18 months.