Mars B Project involved the installation of a new host platform named Olympus at the Mars oilfield in the Gulf of Mexico, with the aim to extend the production life of the deep-water oilfield to 2050 and beyond.

The final investment decision for the Mars B project was approved in September 2010, which was followed by extensive construction works with more than 25,000 people involved in the construction. First oil from the project was produced in January 2014.

The Olympus tension leg platform (TLP) is installed about one mile (1.6km) away from the existing Mars platform. It is the biggest floating deep-water platform deployed in the Gulf of Mexico and the seventh platform owned by Shell. It is also equipped with process facilities to facilitate production from the neighbouring Boreas and South Deimos satellite fields.

In 2013, the Mars field produced at a rate of 60,000boepd. The production rate is expected to reach 100,000boepd in 2016 and the two platforms combined will enable the field to produce one billion barrels.

The development partners of the field are Shell (71.5%) and BP (28.5%).

Mars B Project details

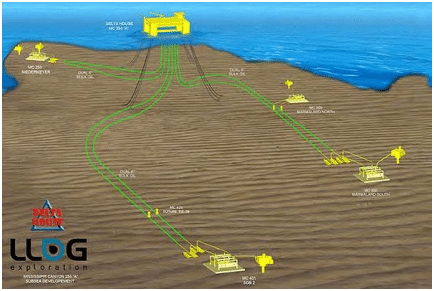

In addition to the installation of the Olympus platform, the project involved the development of subsea wells in the development area and the two satellite fields. New export pipelines were laid tying back to the new West Delta 143C shallow-water drilling platform near the Louisiana coast, from where production is linked to the existing export pipeline infrastructure.

Mars B development area is located approximately 210km (130 miles) south of New Orleans and its reservoirs are located at a depth of 3,050m-6,700m below the sea floor.

The top sections of the wells in the development area were drilled by Noble Corp’s Noble Bully I drilling rig, which is currently working on the wells of the two satellite fields.

Details and construction of the Olympus TLP

The Olympus platform has a processing capacity of 100,000boepd. It features 24 well slots and is equipped with a drilling rig and a helipad. The TLP is connected to 15,000psi-rated subsea trees.

Olympus is 406ft-tall, weighs more than 120,000t and has a combined deck area of 342,000ft². Accommodation facilities are provided for 192 people on the four-storey living quarters of the TLP, which features kitchens, fitness rooms, control rooms and an on-site medical facility.

The tension legs of the platform are fitted with 16 rotationally lined caissons coated with modified high-density polyethylene (HDPE).

The platform’s hull was completed in November 2012 and transported from the construction yard in South Korea to Ingleside, Texas, in June 2013, using Dockwise’s Blue Marlin semi-submersible heavy lift ship.

The shifting of the platform from Ingleside to the project site was carried out in July 2013 using Crowley’s four ocean-class tugboats Ocean Wind, Ocean Wave, Ocean Sky and Ocean Sun, as well as its contracted offshore tugboat Harvey War Horse II. Heerema’s Balder deep-water construction vessel (DCV) was also involved in the installation of the TLP.

Technologies

Project activities were made easier by implementing Shell’s ocean-bottom seismic technology, which provided geologists with greater understanding of the formations below the salt structure.

The platform’s control rooms are connected by fibre optics to the Olympus Remote Control Room (RCR) located at the One Shell Square building in downtown New Orleans, providing easy access to the platform’s operations from onshore.

Contractors involved with the deepwater Mars B Project

The hull of the TLP was constructed by Samsung Heavy Industries, while the fabrication and installation of the topsides were performed by Kiewit Offshore Services.

Engineering and design works, including assistance during commissioning and start-up of the TLP, were provided by William Jacob Management. The certified verification agent (CVA) for the TLP was ABS.

Broadmoor constructed the living quarters of the platform in collaboration with Hi-Tech Electric. The marine instrumentation system for the TLP was supplied by BMT Scientific Marine Services. A corrosion-resistant rotational lining solution for the caissons was provided by RMB Products.

The structural design of the living quarters and structural and piping design of the drilling module were provided by T-REX. The company also rendered engineering assistance for the load-out and transportation of the drilling module.

Up to 80 miles of 16in and 18in-diameter oil and gas pipelines were coated by The Bayou Companies, a subsidiary of Aegion Corporation. The West Delta 143C platform was fabricated by McDermott International.

Dril-Quip was contracted to supply the subsea wellhead equipment, production riser tieback connectors and drilling riser components for the project, under a contract worth $27m.