Delta House Field Development primarily involves the installation of a floating production system (FPS) at a water depth of 4,500ft in the Mississippi Canyon (MC) 254 field in the US Gulf of Mexico.

The partners in the project include LLOG Exploration, Blackstone Energy Partners and LLOG’s co-owners including Ridgewood Energy, ILX, Red Willow Offshore, Calypso Exploration, and Deep Gulf Energy II. The project was approved in December 2012 and initial production from the MC 254 field is expected in the first half of 2015.

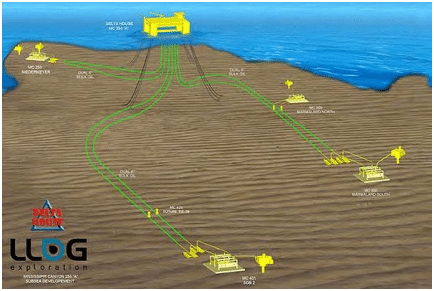

The FPS will also host production from a number of nearby fields including the MC 300 (Marmalard) and the MC 431 (Son of Bluto 2) fields owned by LLOG. Up to seven wells are expected to be drilled to start initial production, of which five have been drilled to date.

The Delta House FPS will have a production capacity of 80,000 barrels of oil per day (bopd) and 200 million cubic feet per day (MMCFD) of gas. The peak capacity of the facility will be 100,000 bopd and 240 MMCFD of gas.

The total investment on the project is expected to reach $2bn, the financing for which will be provided by Arclight.

Delta House project details

The project, besides the installation of the FPS, also involves the installation of an oil export line, a gas export line and other subsea systems including nine subsea trees, four subsea manifolds, five multiphase flow meters and ancillary topside control systems and subsea distribution systems. Up to 200km of infield and export flowlines and risers are expected to be installed as part of the project.

The installation of the FPS will utilise 12 suction pile anchors and 12 pre-set mooring lines. The suction piles will be 85ft long, 16ft in diameter and weigh approximately 150t each.

The production wells for the project are currently being drilled using the deep-water semi-submersible rigs Noble Amos Runner and Sevan Louisiana. Seadrill’s dual blowout preventer (BOP) rig West Neptune is expected to join the other rigs in June 2014 to carry out the drilling activities.

Two initial subsea wells from MC 300 and one initial subsea well from MC 431 will be tied back to the FPS. Two subsea manifolds of MC 300 will be laid approximately eight miles from the FPS, while a single subsea manifold of the MC 431 will be laid approximately 12 miles from the FPS.

Delta House FPS

The semi-submersible hull of the Delta House FPS, designated OPTI-11000, is similar to that of LLOG’s OPTI-EX FPS installed at Who Dat field, but is approximately 50% larger. The Delta House FPS will be capable of hosting 20 risers, enabling simultaneous production from up to nine producing fields with dual flowlines.

The FPS, with a payload capacity of 9,300t, is designed to withstand wind and waves from a 1,000-year storm.

The construction of the hull commenced in March 2013 and took about one year to complete. The shipping of the FPS using a T-class heavy lift transport vessel of Dockwise started in March 2014. The topsides will be fitted at Kiewit Offshore Services Yard in Ingleside, Texas.

Contractors involved with Delta House field development

The semi-submersible hull of the FPS was fabricated by Hyundai Heavy Industries (HHI), while its design was provided by EXMAR. The design and construction of the topsides is being overseen by Audubon Engineering, while the mooring and installation of the FPS at MC 254 will be carried out by InterMoor.

The infield and export flowlines and risers will be installed by Technip, who will also deploy its pipelay and subsea construction vessel CSO Deep Blue to lay the infield lines and the heavy lift construction vessel G1200 to install the export flowlines.

FMC Technologies has been contracted to provide the subsea systems for the project. The contract worth $114m was awarded to the company in January 2013. 2H Offshore has been contracted to provide detailed design for the production and export steel catenary risers (SCRs) which will be tied back to the FPS.

An environmental and facility monitoring system (EFMS) featuring a computer console, topside and subsea remote sensor packages for the FPS will be supplied by BMT Scientific Marine Services.